Types of cover glass for display modules

When developing a new product, the cover for a display is just as critical as the display itself. The actual display component typically does not arrive with any kind of protection, leaving it susceptible to environmental factors and damage from continued use. Depending on product requirements, it is often necessary to add a glass cover to protect the display from impact or scratches while still maintaining optical quality. However, not all glass is created equal. The cost, strength, color options and available thicknesses can impact the decision on which cover glass to use.

Common types of cover glass materials

Soda-lime glass

Soda-lime glass, also known as soda-lime float glass, is the most frequently used type of glass in display modules. It is ideal for any application where cost is a concern, but impact resistance or specific coloration may not be. Due to the high iron content in soda-lime glass, it tends to have a subtle green hue. While this isn’t noticeable when printed on with dark colors, it can give any lighter color (such as white) an unwanted green tint. However, because it’s the least expensive and easiest to attain of all the glass options, it’s omnipresent in display applications.

Low iron soda-lime glass

The same in terms of strength and slightly more expensive than conventional soda-lime float glass, low iron soda-lime glass is a more transparent glass that is almost tint-free. This glass is commonly used as a cover for any product that needs to have a lighter or pure white color around the display, since there’s no green hue to distort the coloring.

Aluminosilicate glass

Aluminosilicate glass, commonly known as Corning Gorilla Glass™ or Dragontrail™ glass by Asahi Glass Co., is a very thin, chemically strengthened glass. One of the strongest types of glass available, aluminosilicate glass has a higher impact resistance than other types of display glass. A few drawbacks to using this glass are that it tends to be much higher in cost to produce and more difficult to attain than other glass options and it is limited in maximum thickness to two millimeters. However, due to its strength and thin profile, it is a popular choice for smartphones and handheld consumer devices.

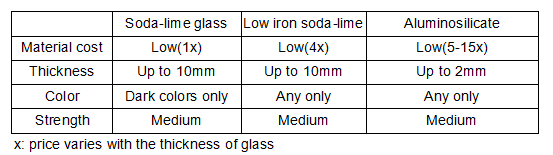

Comparing different types of cover glass

The table below compares the above three types of cover glass:

Microsoft Teams

Microsoft Teams WhatsApp

WhatsApp Email

Email Inquiry

Inquiry WeChat

WeChat

TOP

TOP