The Main Differences in Cover Glass

Hightlights

1. Prince Rupert’s Drops: Glass was first tempered in the 17th Century. Like many great inventions, it came by accident but changed how glass is created.

2. Heat treated glass is a process where glass is heated to a molten state. When the molecules cool, they are realigned into a symmetrical pattern for greater tensile strength.

3. Chemical treated glass is a process where glass is dipped into an ion-exchange solution where smaller potassium molecules are replaced by larger potassium molecules. This reduces surface flaws that occur with untempered glass.

4. Soda lime glass offers a basic, inexpensive solution and is often found in products such as gauges or household window glass.

5. Dragontrail Glass™ is a protective glass that has excellent rigidity with a thin profile at a reasonable cost.

Gorilla Glass™ is a proven brand that offers top notch protection against high impact stress. You will often find this glass in many major smartphones and wearables.

Glass strength is more about equilibrium than anything else. The challenges in the protective glass innovation process are how to adapt to a market that requires thinner and stronger options. There will also be a demand for flexible protection choices in the future.

In the world of display cover glass, the primary objective is to protect thedisplay screen without sacrificing clarity or performance. You may know some of the manufacturers who specialize in making it, you may know some of the benefits of each type, but what is the manufacturing process? Below, we will cover the different ways glass is treated to add durability. We will also look at the types of cover glass you will come across when designing your display.

Three main types of cover glass typically found on displays are soda-lime, Dragontrail Glass™, and Gorilla Glass™. Before we get into the specific details of what differentiates them, it is important to understand what tempered glass is and what the different processes are. The two ways to create tempered glass are based on either a chemical or physical reaction. They are different in the process, but the result is the same; to create a glass that has higher rigidity and performance. Some may recall the principles of tempered glass and how it is made but for others, here’s a quick refresher.

A Bit of History - Prince Rupert’s Drops

The early 17th Century, a drop of molten glass was accidently dipped into cold water. What occurred was the first instance of heat tempered glass. Though this first instance was in the Northern German/Netherlands region, Prince Rupert brought the process to the Royal Society of London where early scientific studies were performed (hence the name). In this method, the outer layer cools down much quicker than the inner portion, resulting in a tadpole-shaped droplet. It contracts inside, creating a compressive stress on the exterior while the interior stays in a state of tensile stress (leading to expansion). High residual stress is the result of removing the original cause of the stress, making it impact resistant to dropping being or hit with an object. However, if the tail gets chipped, the glass shatters in an explosive manner. Now let’s look at the different tempering processes.In

Heat Tempered Glass

Heat tempered glass (not to be confused with heat treated) is a process where the glass is heated to a soft state much like that of lava. The temperature can range anywhere between 1,050 °F (566 °C) to 1,150 °F (621 °C). During this thermal treatment, recrystallization occurs, and the molecules are realigned into a straightened pattern. If you think of a stack of cards, it is at its strongest when the cards are lined up into perfect triangles. With untempered glass, the molecules are positioned more randomly with less structural integrity. One positive feature that is ideal for the automotive industry is that when heat tempered glass breaks it shatters into small shards, making it safer. Heat tempered glass can also be used in applications that require higher temperature tolerances like coffee pots or oven glass. The overall benefit is the durability factor. Per the Mohs scale of mineral hardness where the range is 1-10, the average hardness of heat tempered glass is about 7. To put that into perspective, the hardness of pencil lead is around 3 and a diamond is at a 10.

Chemical Tempered Glass

Chemically tempered (also known as chemically strengthened) glass is a process where untempered glass is submerged into a molten vat of approximately 716°F (380°C) of potassium nitrate from 4 to 30 hours, creating an ion-exchanging reaction. Larger potassium ions replace smaller sodium ions, filling voids, which then increases its stability. The glass maintains its optical clarity with little warping or strain patterns that can sometimes occur with heat tempered glass. One of the big benefits of chemically tempered glass is the ability to cut it after the strengthening process has occurred, which is not possible with heat tempered glass. Like heat tempered glass, the Mohs hardness of heat tempered glass is at a 7 or more.

Below are some main types of cover glass you would find protecting a display.

Soda-lime Glass

Soda-lime glass is one of the most prevalent types of glass made. It is chemically tempered and has been around for a long time. When you try to imagine soda-lime glass, think of any glass you have seen that has the green tint along the edge. A glass furniture shelf may be a good example of this, but you can find this glass in soda bottles, glass bakeware, and many other consumer products. In regards to a display cover glass, soda-lime glass is the least expensive option. It is readily available and has been market approved for a long time. Because it is chemically tempered, it is thicker than other substitutes and will sometimes have the aforementioned greenish hue. It is still a great product and solution if you find yourself on a budget but needing durability.

Dragontrail Glass™

DragontrailGlass™ isa product manufactured by Japanese company Asahi Glass Co.®, who has been in business since 1907. It is a durable product made of an aluminosilicate material which is composed of aluminum, oxygen, and silicon. It goes through both chemical and heat tempering process. During the chemical tempering stage, untempered glass put through a High Ion Exchange™ procedure where an even, flat sheets of glass are created, and surface tension is used as a strengthening agent. This makes it ideal for components where weight or size conservation is important. It then goes through a heat tempered float glass manufacturing process where the chemically tempered glass is floated in a liquid state over molten tin, which creates an even stronger compound. This is what makes it 6x stronger than soda-lime glass. Some of the advantages of Dragontrail Glass™ includes high scratch resistance, it is composed of non-hazardous materials, and can be made in various thicknesses. Dragontrail Glass™ is also great for mobile devices because it is designed around the idea that it will be integrated with a touch panel. It is more expensive than soda-lime glass, but it is not the most expensive brand in the market. It is also not as well-known as its competitors but certainly stands with the best of them. Overall Dragontrail Glass™ is a great product that combines high strength with a slim profile that can be integrated to provide significant added value and the ever-important durability.

Gorilla Glass™

Coming Incorporated® has been solving technical issues for customers for over 160 years. One of their highly acclaimed products is Gorilla Glass™. Gorilla Glass™ is a favorite product that can be found in many smartphones, computers, and tablets. The secret to Gorilla Glass™ is how it is produced. It goes through a chemically tempered manufacturing process and is made of alkali-aluminosilicate material. T, the raw material is blended into a glass composition and is then melted into a thin layer. The thin glass then goes through a chemical strengthening process where it is submerged in a hot (750 °F or 400 °C) potassium salt ion exchange solution. This gives it a layer of high residual compressive stress at the surface and increases the strength while minimizing flaws which could otherwise create points of failure. Some of the overall benefits of Gorilla Glass™ includes high clarity, increased durability, and impact resistance. Gorilla Glass™ can also feature scratch resistance capabilities with a specialized Oleophobic coating that increase the hardness up to 9 on Mohs scale. It is thin, lightweight, and has many customizable options to suit your needs.

Gorilla Glass™ was conceived for mobile applications and is a very popular brand among larger manufacturers. There have been 4 phases developed as the technology continues to evolve. In its latest version, Gorilla Glass™ 4 features antimicrobial properties with high damage resistance. When you are looking at the later generations of Gorilla Glass™, they are more expensive than other options due to their high performance and thin makeup. Gorilla Glass™, like the Dragontrail Glass™, is a great product, particularly if you require high-quality protection that has been rigorously tested.

How They Stack Up

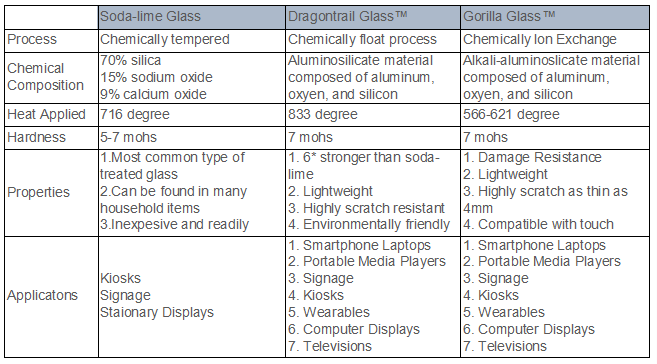

In a side by side comparison, you can’t go wrong with either Gorilla Glass™, Dragontrail Glass™ or soda-lime. They each have their pros and cons. Gorilla Glass™ is certainly a proven product. It offers the slimmest option, which can be important if something like weight is a concern. It also has excellent protection in case your product may be dropped or requires high rigidity. With that said, the big downside is you will pay a premium. For Dragontrail Glass™, it also has outstanding performance and durability for high rigidity and drop protection. It is not as well know so you do not have to spend a premium on it. If standard protection is all you seek, then the soda-lime glass is a great solution. If you are trying to protect a display incorporated into a gauge, for example, you may not need a high performing glass. Soda-lime will protect your display, and it is a cost effective solution.

Microsoft Teams

Microsoft Teams WhatsApp

WhatsApp Email

Email Inquiry

Inquiry WeChat

WeChat

TOP

TOP