Introduction to the structure and working principle of polarizer of optical film

One of the important performances of IT equipment such as TVs, smartphones, and car instruments is image quality. In order to create a display with clear image quality, "polarizer" is an indispensable material.

The natural light we usually see vibrates in all directions and spreads in all directions. When the natural light vibrating in multiple directions passes through the polarizer, it is converted into light waves vibrating in one direction. Without the polarizer, the screen will look blurry. This is why the polarizer is called the "digital shutter".

LCD (Liquid Crystal Display) is a transmissive display that uses liquid crystal between two polarizing plates to change the direction of light or adjust the intensity.

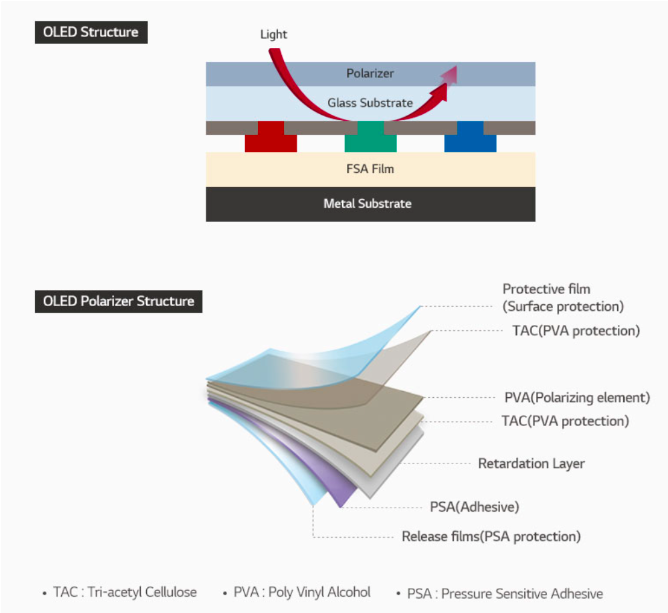

In contrast, OLED (Organic Light-Emitting Diode) is a self-luminous display that emits light by transmitting electronic signals to the OLED device.

01

Structure of polarizer

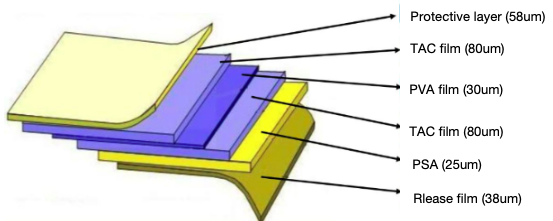

Polarizer is mainly made of PVA film, TAC film, protective film, release film and pressure-sensitive adhesive. The basic structure of polarizer is shown in the figure below:

The core film material for polarization in polarizers is PVA film. After dyeing, PVA film absorbs iodine molecules with bidirectional absorption function. Through stretching, the iodine molecules are arranged in order on the PVA film, forming a polarizing film with uniform bidirectional absorption performance, and its transmission axis is perpendicular to the stretching direction. (The stretching direction is also known as the absorption axis.

02

Working principle of polarizer

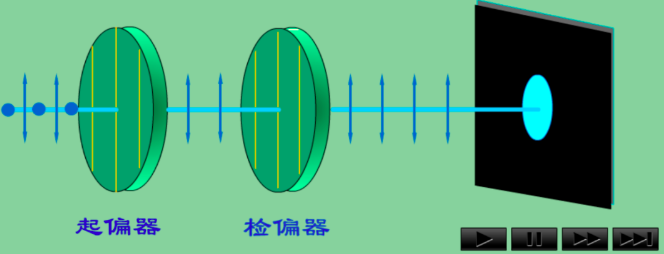

LCD uses the optical rotation of liquid crystal. Liquid crystal molecules with moderate thickness can rotate the polarization direction of light by 90° or 270° (when voltage is applied, the liquid crystal molecules stand up due to the electric field and do not change the polarization direction of light). Adding two polarizers can turn the entire liquid crystal box into a light switch. One is a polarizer (downward, close to the light source), and the other is an analyzer (close to the eyes).

If there is no polarizer, the incident light is circularly polarized light, and the outgoing light is also circularly polarized light, so there will be no image. It will just be white. As for the RGB filter film inside the LCD, green is needed to display red, blue is completely off, and red is on, so it looks red. If RGB is fully on due to the failure of the polarizer, then it may be a complex light - white light.

Polarizer can control the polarization direction of a specific light beam. When natural light passes through the polarizer, the light with a vibration direction perpendicular to the transmission axis of the polarizer will be absorbed, and only the polarized light with a vibration direction parallel to the transmission axis of the polarizer will be transmitted.

Polarizers only allow light to pass in a single direction, so the light can be controlled by arranging the upper and lower polarizers vertically.

When the incident light from the backlight passes through the polarizer, liquid crystal and orientation film, the output light has a specific directional characteristic, that is, most of the light emitted from the screen has a vertical direction. Therefore, the angle of LCD has certain limitations; if we watch a completely white screen from a very oblique angle, we may see black or color distortion.

Generally speaking, the upper and lower angles should be less than or equal to the left and right angles. If the viewing angle is 80 degrees to the left and right, it means that the screen image can be clearly seen at a position 80 degrees from the normal of the screen. However, due to different visual ranges of people, if you are not standing in the best viewing angle, the color and brightness you see will be wrong.

The display principle of LCD determines that its viewing angle is not ideal. In order to increase the viewing angle, some manufacturers have developed various wide-viewing angle technologies to try to improve the viewing angle characteristics of LCD monitors, such as IPS LCD panels, which can increase the viewing angle of LCD monitors to 160 degrees or even more.

03

Classification of polarizersPolarizers have a wide range of applications. They can be used not only as polarizing materials on LCDs, but also in sunglasses, anti-glare goggles, filters for photographic equipment, anti-glare treatment of car headlights and light regulators. Others include polarizing microscopes and special medical glasses.

a. Classification of polarizers by function

Transmission polarizers Reflection polarizers Semi-transmission and semi-reflection polarizers Compensation polarizers

b. Classification of polarizers by dyeing method

Iodine-based polarizers: PVA is combined with iodine molecules, which is the main method for producing polarizing films today. It is easy to obtain optical properties with high transmittance and high polarization, but the ability to withstand high temperature and high humidity is poor.

Dye-based polarizers: Organic dyes with dichroic properties are adsorbed on PVA and extended and oriented to give it polarization properties. It is not easy to obtain optical properties with high transmittance and high polarization, but the ability to withstand high temperature and high humidity is good.

c. Polarizers are classified by the type of polarizing materials

Metal polarizers: metal salts such as gold, silver, and iron are adsorbed on polymer films and then reduced to make the rod-shaped metal have the ability to polarize. This method is no longer used in production.

Iodine polarizers: PVA and iodine molecules are composed of PVA, which is the main method for producing polarizing films today.

Dye polarizers: organic dyes with dichroic properties are adsorbed on PVA and extended and oriented to give it polarizing properties;

Ethylene polarizers: PVA is dehydrated using acid as a catalyst to make the PVA molecules contain a certain amount of ethylene structure, and then extended and oriented to give it polarizing properties.

04

Polarizer surface treatment

Common surface treatment methods include: Anti-glare treatment (AG) Anti-glare + low reflection treatment (AG + LR) Transparent hardening + low reflection treatment (CHC + LR) Transparent hardening treatment (CHC) Anti-reflection treatment (AR), etc.Different surface treatment methods can meet the application requirements of different terminals. For example, CHC treatment is mostly used in touchable mobile electronic devices. At present, the above surface treatment has been widely used in various electronic products. Its production and processing process is a typical wet coating process.

05

Key points of polarizer design

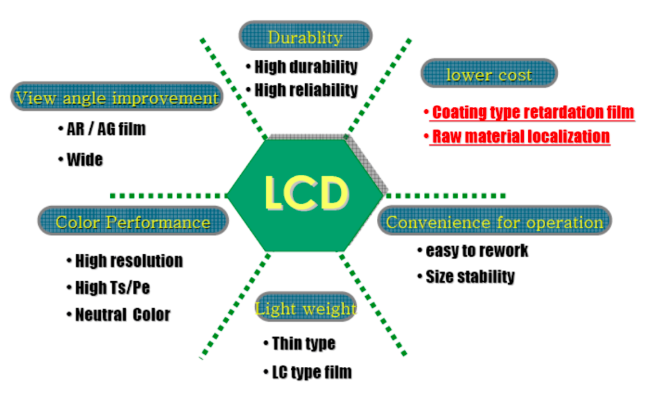

The design and selection indicators of polarizers mainly include optical properties, mechanical properties and reliability. On the premise of meeting these three aspects, the cost aspect should be considered.

Optical properties mainly refer to parameters such as transmittance, polarization and hue of polarizers; if the lower polarizer filters light in the X direction, the upper layer can only filter light in the Y direction. If the upper and lower layers are in the same direction, users will not be able to see anything.

Although the LCD screen is working normally, the naked eye cannot see polarization.

In terms of matching with the backlight, the absorption axis of the lower polarizer must be perpendicular to the penetration axis of the backlight DBEF film, otherwise the backlight will not be able to penetrate the lower polarizer; secondly, if the backlight uses a grating film (anti-peep film), pay attention to the angle of the grating film, otherwise it is easy to produce moiré problems.

Mechanical properties mainly include the warpage of the polarizer, the bonding strength of the polarizer pressure-sensitive adhesive and the thickness of the polarizer; Reliability is an indicator of the durability of the polarizer. The evaluation method is to place the polarizer in an environmental test box such as high temperature, low temperature, high temperature and high humidity for a certain period of time, and then check the changes in its appearance and optical properties.

06

Prospects for the development of polarizers

In fact, traditional polarizer technology can no longer meet the ever-changing needs of new display technologies. In particular, as mobile phone products are becoming thinner and thinner, higher requirements are placed on the thinness, high transmittance, and high weather resistance of polarizer materials.The built-in polarizer (In-Cell Polarizer) technology directly prepared inside the display device integrates the polarizer with the display device. Its unique advantages such as ultra-thinness, high transmittance, environmental tolerance, and low cost are increasingly valued by the display industry.

In particular, the development of flexible OLED and flexible LCD has put forward an urgent need for the development of built-in polarizers. The thinner the overall thickness of the flexible display screen, the better the flexibility of the material, and the smaller the curvature radius that can be achieved.

The plastic substrate for making external polarizers for LCDs will lead to flexible display issues such as poor display quality and narrow viewing angle characteristics. For example, the thickness of the polarizer and phase difference plate causes the problem of poor flexibility.

Microsoft Teams

Microsoft Teams WhatsApp

WhatsApp Email

Email Inquiry

Inquiry WeChat

WeChat

TOP

TOP